Begin immediately generating revenue and enhance your brand with goDesk®. goDesk® was designed to help manufacturers, distributors and direct sellers capture the expanding travel office and travel convenience market segment with innovative OEM compatible products and user-installed after-market products.

Engineering: Speed to Market - Section No. 1

Be in the Market with goDesk® in Less Than 30 Days

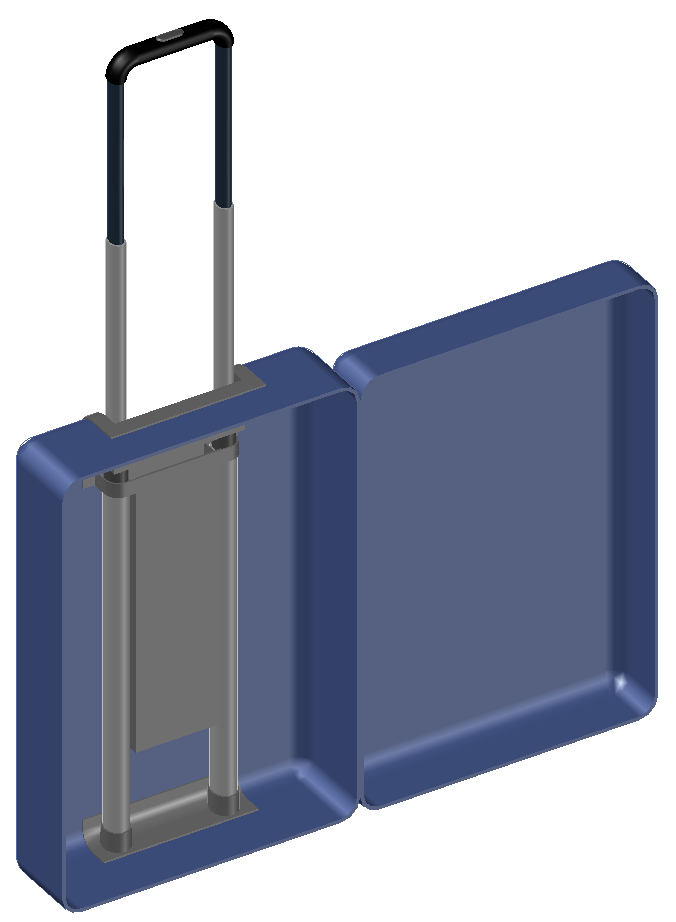

These products transform standard roller bags into multi-functional luggage for a fraction of the cost of specialized luggage providing travel office and travel convenience capability. goDesk® design leverages the most advanced computer-enabled manufacturing technologies and has already completed multiple iterations of model testing, functional testing, usability testing, stress testing and manufacturing feasibility testing. goDesk® is production ready now.

Engineering: Speed to Market - Section No. 2

Universal Design for Oems and After-Market Accessories

goDesk® was designed to be compatible with nearly any standard roller luggage brand. goDesk®’s unique and patent pending design transforms an OEM standard product into integrated luggage with travel office and traveler convenience functions with virtually no production changes. goDesk® requires no modification to luggage size, dimensions, luggage poles or handles.

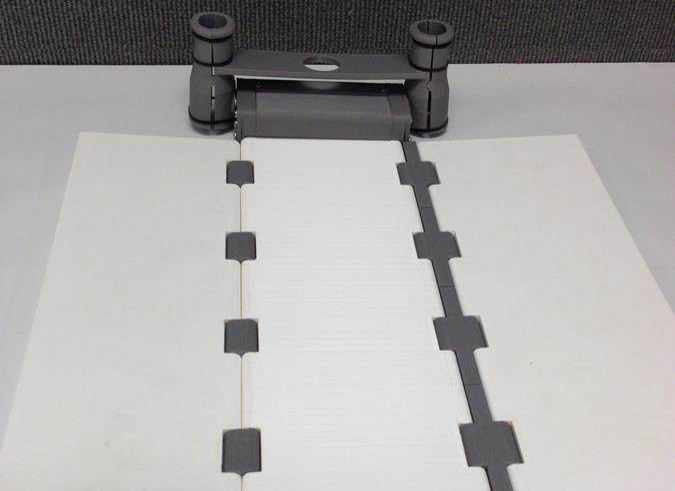

goDesk® is also available as an after-market product that can be installed by the consumer in less than 10 minutes, allowing you to reach the huge existing installed base of roller luggage. Advanced software modeling and “hands-on” functional demonstrations have tested goDesk® to validate its strength and stability attributes, all within an ultra-lightweight form factor weighing less than one pound.

Engineering: Speed to Market - Section No. 3

Profile of Design & Engineering Team

The goDesk® design team comprises a diverse, multi-faceted group with expertise in a large number of consumer applications. Design team members have also lead breakthrough innovations in areas such as drone engineering. The team leveraged tools and methods aimed at design flexibility to envision and create goDesk® such that components can be produced cost-effectively and in a timely manner.

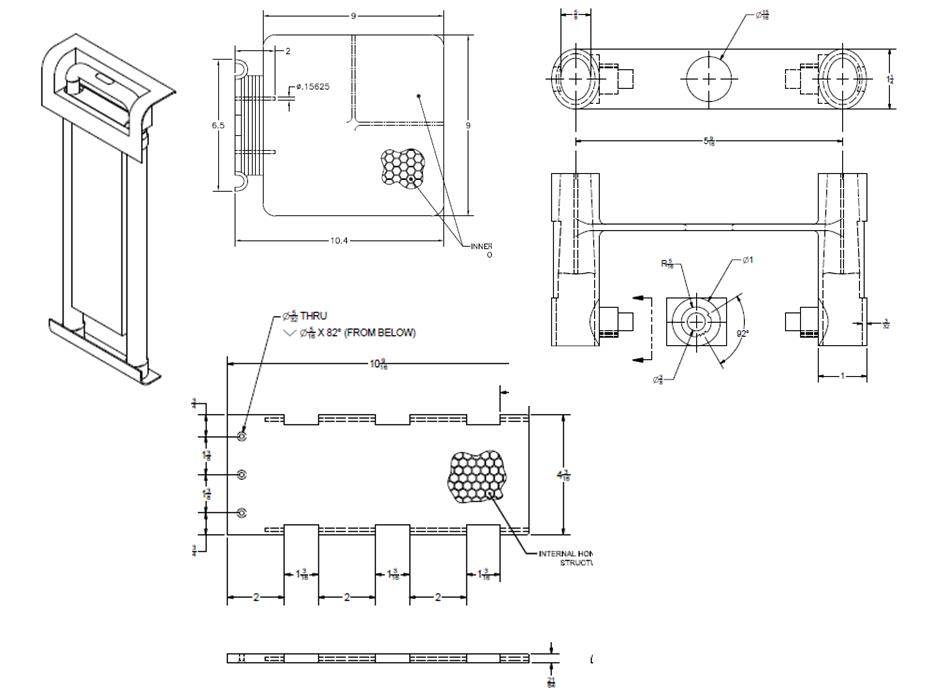

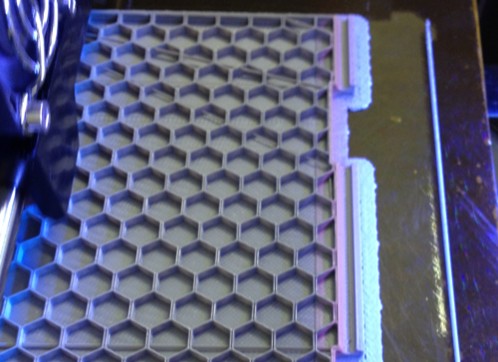

The team applied advanced manufacturing and design technologies throughout the full product life cycle of goDesk®. Additive Manufacturing (AM) and 3D Printing (3DP) technologies were used to create goDesk® element design and components directly from three-dimensional computer-generated models. The team employed Rapid Prototyping (or RP) to create physical prototypes directly from the computer-generated models, and production-ready goDesk® components have been iteratively evolved from the prototype designs.

Engineering: Speed to Market - Section No. 4

Design & Engineering Team Continued

- Patents pending for each goDesk® product, including more than five distinct elements of proprietary and patented design.

- goDesk® trademarks secured for product naming rights, internet domains, and social media.

- goDesk® designed and engineered by award winning design team, including design engineers with patents granted for top-secret military contracts

- Advanced computer-aided design software and prototyping process utilized throughout the design, engineering and production modeling process of goDesk®.

- goDesk® developed using rapid design-to-demonstration prototyping capability utilizing 3D printer technology; product development leveraged iterative design, test and deploy methods.

The goDesk® designers drove an innovative and creative process, leveraging tools and methods aimed at design and functional flexibility. Designed to be compatible with virtually all standard roller luggage brands, goDesk’s unique and patent pending design transforms an OEM standard product into integrated luggage with travel office and traveler convenience functions.

The team employed Rapid Prototyping (or RP) to create physical prototypes directly from the computer-generated models, and production-ready goDesk® components have been iteratively evolved from the prototype designs. goDesk® design leverages the most advanced computer-enabled manufacturing technologies and completed multiple iterations of model testing,functional testing, usabilty testing, stress testing and manufacturing feasibility testing.

goDesk® products are fully supported with an integrated library of design artifacts and objects, and manufacturing models that enable the ability to quickly and directly transition into production.

Engineering: Speed to Market - Section No. 5

Overview of Design Process

goDesk® design objectives require no modification to luggage size, dimensions, luggage poles or handles. Any company looking to bring goDesk® to market can utilize its own production capacity, or alternatively, leverage pre-selected manufacturers to speed time to market even further. These selected potential manufacturing partnerships and job shop manufacturers have been assessed and have previewed goDesk® production planning details.

In order to speed time to large-scale manufacturing and production, Additive Manufacturing (AM) and 3D Printing (3DP) technologies were used to create goDesk® elements and components directly from three-dimensional computer-generated models. AM and 3DP were utilized in parallel with batch production techniques to provide opportunities for speed and cost advantages. In conjunction with alternative manufacturing techniques, this approach positions goDesk® for large-scale such as plastic injection molding, vacuum molding, die casting, etc.

Access goDesk® Secured Content for All the Details

Contact us today to receive your personal codeword to access extensive proprietary design and engineering documentation. Learn more about goDesk® and how you can be capturing new market share within weeks with goDesk®.

Contact Us